Green Methanol

Waste-to-Methanol Process and Alignment with IMO 2030

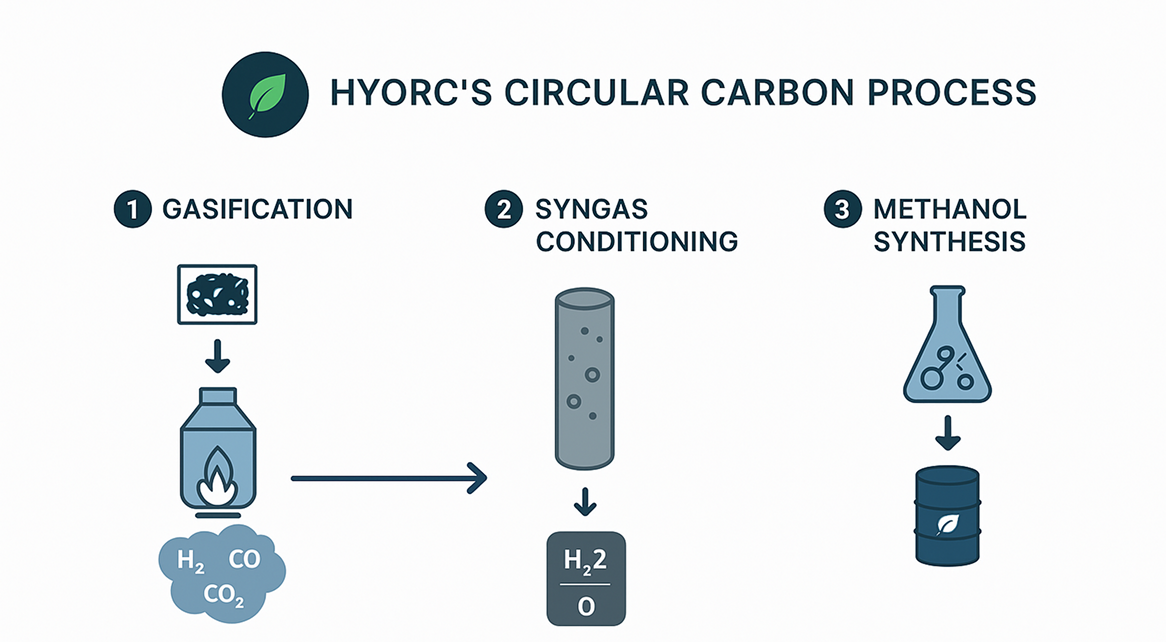

RDF is fed into HyOrc’s high-efficiency external-combustion gasifier operating at 850–1,100 °C.

The controlled oxygen environment converts the waste into syngas, primarily a mixture of hydrogen (H₂), carbon monoxide (CO), and CO₂.

Minimal tar formation and a stable calorific value make the gas suitable for downstream synthesis.

The raw syngas is cleaned and balanced to achieve the ideal stoichiometric ratio (H₂/CO ≈2) required for methanol synthesis.

Impurities such as particulates, sulfur, and chlorine are removed through filtration and wet scrubbing.

Conditioned syngas is catalytically converted into methanol (CH₃OH) under moderate pressure and temperature.

By-products include small quantities of pyrolysis oil and inert ash, both recyclable or re-usable within industrial supply chains.

This is the same carbon reaction that nature performs over geological timescales, condensed by HyOrc into a clean industrial process that takes hours instead of millions of years.

IMO 2030: Decarbonising Maritime Transport

These targets are driving an accelerated shift away from heavy fuel oil and LNG toward green methanol, which the IMO recognises as one of the most scalable carbon-neutral fuels available today.

Major carriers such as Maersk, CMA CGM, and COSCO have already committed to methanol-powered fleets.

Global methanol demand for shipping alone is projected to exceed 30 million tonnes per year by 2035.

How HyOrc Enables IMO 2030 Compliance

IMO 2030 Requirement |

HyOrc Solution |

| Carbon-neutral fuel adoption | HyOrc’s green methanol from waste offers near-zero net CO2 emissions, eliminating dependence on fossil methanol |

| Lifecycle emissions reduction | Using existing waste streams avoids upstream emissions from crude extraction and refising. Each tonne of methanol displaces roughly 1.4t CO2-eq from fossil fuels. |

| Scalability and localisation | HyOrc’s modular 300 TPD RDF units can be deployed near ports or industrial hubs, producing fuel exactly where it’s needed – reducing logistics emissions |

| Energy security | Ships powered by methanol produced domestically from waste improve fuel independence for EU member states |

| Circular economy compliance | Converts a mandated waste-management liability (RDF) into an IMO-compliant export commodity |

Strategic Positioning

- Each HyOrc 400 TPD-methanol platform can offset >350,000 t CO₂ per year relative to conventional marine fuels.

- Waste feedstock qualifies under EU Renewable Energy Directive II (RED II) as an advanced biofuel pathway.

- The resulting methanol is fully compatible with existing ship engines and port bunkering infrastructure, giving immediate market entry.

In short: HyOrc transforms waste into an energy commodity that directly satisfies the IMO 2030 decarbonisation roadmap, while solving Europe’s RDF landfill bottleneck and creating domestic, circular fuel independence.